Medium frequency induction heating production line 二維碼

Medium frequency induction heating production lineIt is a device that uses the principle of medium frequency induction heating to heat metal materials. The entire set of equipment can automate the entire process from loading, heating to discharging metal workpieces, almost in an unattended state.Medium frequency induction heating production lineWidely used in heat treatment processes such as heating, quenching, annealing, and tempering of various metal materials。It is especially suitable for forging heating production lines, round steel heat treatment heating production lines, and round or square steel rolling production lines. It achieves fast and non-contact heating throughout the entire heating process, which is unmatched by other heating equipment at present. here,Haishan electric furnaceThe editor will introduce this setMedium frequency induction heating production line。

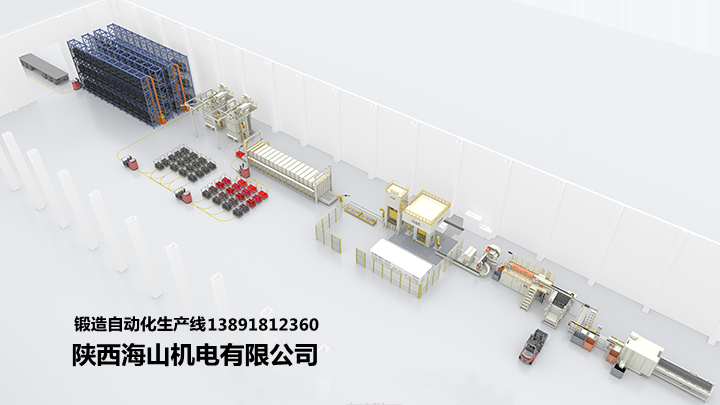

one,Medium frequency induction heating production lineComposition: Medium frequency induction heating production lineIt is mainly composed of medium frequency power supply, sensor, rhythm controller, sensor furnace frame, cooling system, cylinder pushing system, automatic feeding system, temperature measurement and sorting system, conveying system, discharging system and control system. two,Medium frequency induction heating production lineApplications: Medium frequency induction heating production lineGenerally speaking, it includes medium frequency induction quenching and tempering production lines, medium frequency induction forging production lines and medium frequency induction rolling production lines. 1. The medium frequency induction quenching and tempering production line includes anchor bolt quenching and tempering equipment, steel rod quenching and tempering heat treatment production line, anchor bolt quenching and tempering system, oil steel pipe (oil drill pipe, drill collar) heat treatment, steel rod quenching and tempering heat treatment production line, metal heat treatment Production line, metal heat treatment production line, plate quenching and tempering heat treatment production line, etc. 2. The medium frequency induction rolling production line includes a steel ball production line, a steel billet heating and replenishing production line, a round steel rolling and heating production line, a continuous casting billet heating production line, and a stainless steel pipe heating production line. 3. Medium frequency induction forging production line includes induction heating forging and diathermy production line, drill pipe end thickening forging line, wear-resistant belt welding preheating, bending heating, gas (oil) pipe anti-corrosion spray heating, warm forging heating production line, Round steel forging production line

three,Medium frequency induction heating production linespecialty: 1、Medium frequency induction heating production lineIt can achieve intelligent and precise temperature control, achieve constant temperature in the furnace and implement an intelligent synchronous three-selection system to avoid the flow of unqualified materials. 2、Medium frequency induction heating production lineHeats up quickly, reducing oxidation and decarburization. The principle of induction heating is electromagnetic induction, and heating is generated inside the material. As a result, the material heats up quickly and with little oxidation. 3、Medium frequency induction heating production lineImplement an intelligent protection system, with all alarm information displayed and stored in Chinese. 4、Medium frequency induction heating production lineHigh automation. Haishan electric furnaceMedium frequency induction heating production lineThe system uses an automatic feeding system and an automatic unloader for fully automatic operation. 5、Medium frequency induction heating production lineHeats evenly. The temperature difference between the surface and core is small. Operators can precisely control the temperature through the temperature control system to ensure product quality. 6、Medium frequency induction heating production lineThe heating rhythm can be designed based on productivity, and the heating speed is designed based on heating power, heating temperature, and weight of the heated workpiece. The heating speed can be as fast as 1 second and can be adjusted arbitrarily. 7. It can work continuously for 24 hours. It uses the principle of electromagnetic induction to quickly induce a large eddy current inside the metal material in the alternating magnetic field, thereby heating the metal material to 950~1/250 degrees. 8、Medium frequency induction heating production lineThe heating range is very wide, it can have various forms of heating methods, and can heat a variety of workpieces. 9、Medium frequency induction heating production lineThe induction furnace body is easy to replace: it is equipped with a quick-change connector for easy and fast operation. 10、Medium frequency induction heating production lineLow energy consumption and no pollution. Compared with other heating methods, induction heating has the advantages of high heating efficiency, low energy consumption, and no pollution.

If anyMedium frequency induction heating production lineFor needs, please call Manager Guo at 13891812360; moreMedium frequency induction heating production lineFor information, please follow the website of Shaanxi Haishan Mechanical and Electrical Co., Ltd. http://www.hszpl.com |